Processes

TECHNOLOGY, CAPACITY AND CAPABILITY

FOUNDRY PROCESS

Foundry processes can be divided into two types:- ferrous foundries and non-ferrous foundries. Foundry processes involve making the mould and the core, melting and pouring the metal into the mould, and finally removing the mould and core and finishing the product. Although different processes differ in the number of steps required to make the final product.

- Proccess Optimization

- Simulation

May

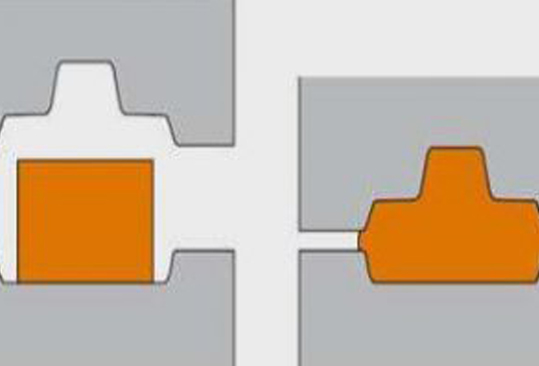

METAL FORMING PROCESS

- Simulation Based Die Design

- Process Parameter Optimization

- Special Materials Forgings

June

POWDER ATOMIZATION

Atomized powder is a powder produced by the dispersion of a molten material into particles by a rapidly moving gas or liquid stream or by mechanical dispersion. Atomization is the dominant method for producing metal and pre-alloyed powders from: Aluminum. Brass.

- Atomizing Plant Design

- Powder Treatment

September

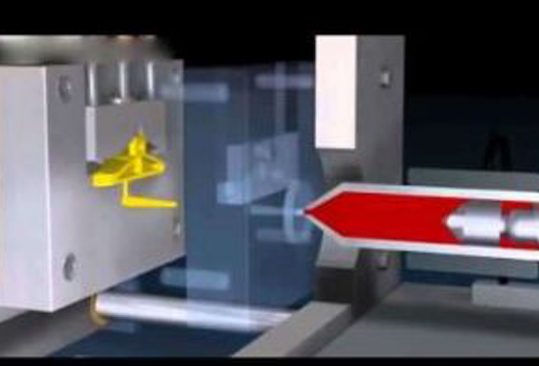

METAL INJECTION MOULDING

Metal injection molding (MIM) merges two established technologies, plastic injection molding and powdered metallurgy. This frees designers from the traditional constraints associated with trying to shape stainless steel, nickel iron, copper, titanium and other metals.

- Plant Design

- Equipment Selection

February

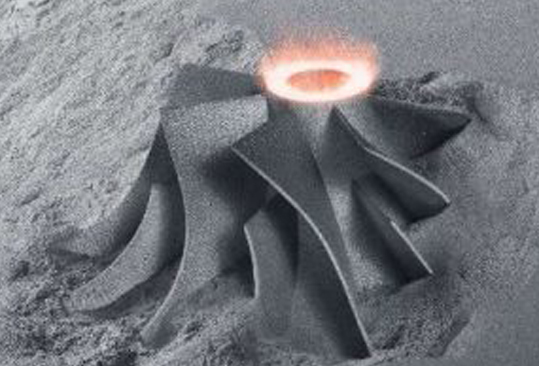

METAL ADDITIVE MANUFACTURING

Metal additive manufacturing is the also Known as 3D printing

- New Product Design

- Powder Selection

- Build Parameter Optimization

July